The commonly used connections for steel structures

- Share

- publisher

- ZYM

- Issue Time

- Sep 22,2023

Summary

Steel structure is a structure mainly made of steel, which is one of the main types of building structures.

Steel structure is a structure mainly made of steel, which is one of the main types of building structures. Steel is characterized by high strength, light weight, and high stiffness, making it particularly suitable for building large-span, ultra-high, and ultra-heavy buildings; The material has good plasticity and toughness, can undergo significant deformation, and can withstand dynamic loads well; Short construction period; Its high degree of industrialization allows for specialized production with high mechanization.

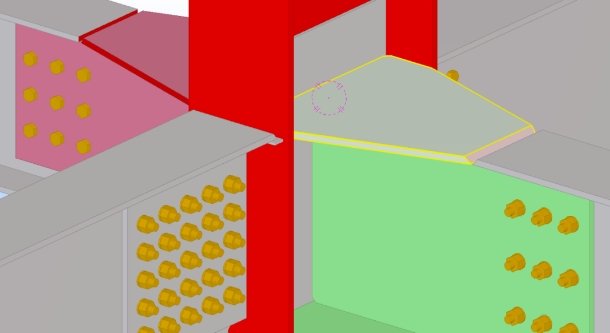

The commonly used connections for steel structures include weld connections, bolt connections, and rivet connections

1. Weld connection is the process of locally melting the welding rod and the weldment through the heat generated by the arc, and then cooling and condensing them to form a weld, thereby connecting the weldment into a whole.

The advantages are: not weakening the section of the component, saving steel, simple structure, convenient manufacturing, high connection stiffness, good sealing performance, easy to use automated operation under certain conditions, and high production efficiency.

The disadvantage is that the heat affected zone formed by welding high temperature in the steel near the weld may cause some parts of the material to become brittle; During the welding process, the steel is subjected to uneven distribution of high temperature and cooling, resulting in residual welding stress and deformation in the structure, which has a certain impact on the bearing capacity, stiffness, and performance of the structure; Due to the high stiffness of welded structures, local cracks can easily propagate to the entire structure, especially at low temperatures where brittle fracture occurs; The plasticity and toughness of weld joints are poor, and defects may occur during welding, leading to a decrease in fatigue strength.

2. Bolted connection is the process of connecting the connecting parts into a whole through bolts, which are fasteners. There are two types of bolted connections: ordinary bolted connections and high-strength bolted connections.

The advantages are: simple construction process, convenient installation, especially suitable for on-site installation and connection, as well as easy disassembly, suitable for structures that require disassembly and temporary connections.

The disadvantage is that holes need to be drilled and aligned during assembly, which increases manufacturing workload and requires high manufacturing accuracy; Bolt holes also weaken the cross-section of the component, and the connected parts often need to overlap with each other or add auxiliary connecting plates (or angle steel), resulting in more complex construction and steel consumption.

3. Rivet connection refers to the process of quickly inserting a semi circular prefabricated rivet head at one end into the hole of the connector after the rivet rod is burned red, and then using a rivet gun to rivet the other end into a rivet head to achieve a secure connection.

The advantages of riveting are: reliable force transmission, good plasticity and toughness, easy quality inspection and assurance, and can be used for heavy and directly bearing dynamic loads in structures.

The disadvantage is that the riveting process is complex, manufacturing requires labor and materials, and labor intensity is high, so it has been basically replaced by welding and high-strength bolt connection.

Read More

For further information feel free to contact us

Email:sales@zyminfra.com

Tel/Whatapp:0086-18561962040