What types of finishes are available for prefab steel structures?

- Share

- Issue Time

- Dec 1,2023

Summary

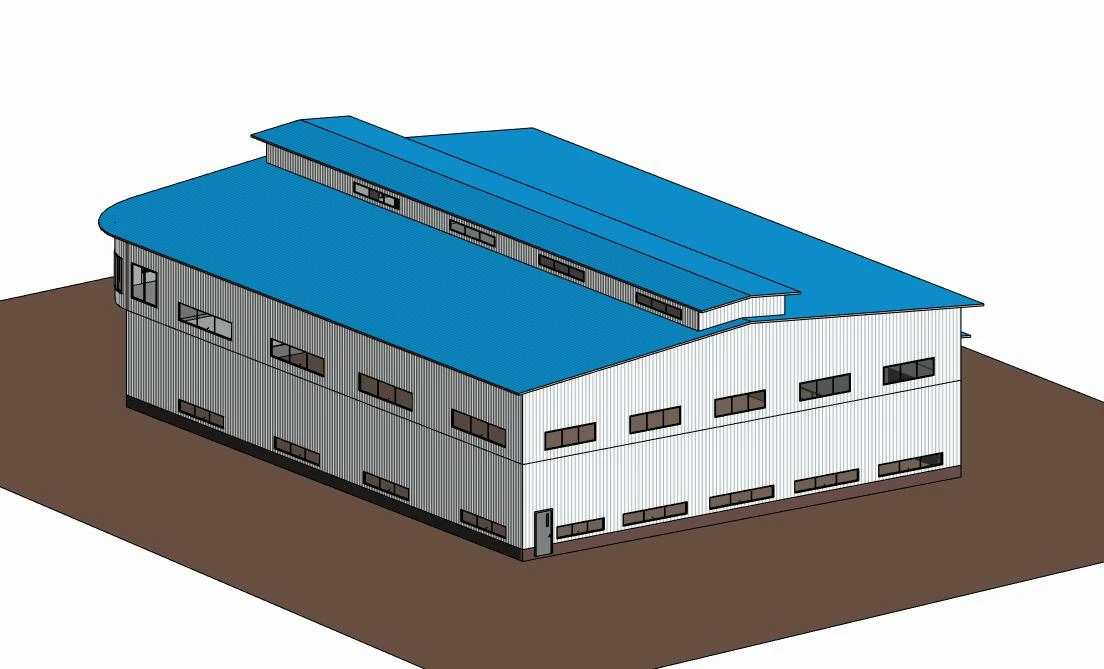

Prefab steel structures can be finished in a variety of ways to suit the needs of the customer.

structure manufacturers with 20+ years of group experience in prefabricated steel material production,+126,000㎡steel structure building construction in service. ZYM has three modern base centers, one center is responsible for design and R&D, one center handles production ,one center is for the sales and service.The group maintains production facilities for high-quality prefabricated steel,steel structure with an annual output of 50,000-60,000 tons of steel structure.ZYM Team Group acts as a real partner, providing excellent products as well as technical service. Our role goes beyond a designer and manufacturer. We consider our clients part of the team, supporting the as partners. As such, we are with them each step of the way, from engineering customized steel structure solutions to the manufacturing and installation of the steel structure building.Our experience has earned us a reputation as a dependable partner.Manufacturing facilitiesProviding safety and quality steel structure systems, ZYM Team Group has a strong focus on manufacturing all major components of steel structure building ,we have 5 steel structure production lines. ZYM covers an area of more than 50,000 square meters, with excellent equipment, numerical control technology and high degree of automation. Our products are approved by PHI,TUV,BV,CE etc.ZYM Team Group focus on creating and protecting value. We offer the full range of steel structure products, from steel material to highly engineered building systems, as well as accessories. Our full production line offers high-quality products at competitive prices. We pay attention to every little detail to ensure our steel structure more perfect.

An Ultimate FAQ Guide:

2.Can prefab steel structures be used for commercial and residential buildings?

3.Are there any limitations on interior layout for prefab steel structures?

4.How does the construction time of prefab steel structures compare to traditional buildings?

5.Are there any limitations on the size of a prefab steel structure?

6.What type of warranties are offered for prefab steel structures?

7.Can prefab steel structures be designed to withstand extreme weather conditions?

8.Are prefab steel structures suitable for multi-story buildings?

9.How does the weight of prefab steel structures impact transportation and installation?

10.Are there any size restrictions for transportation and delivery of prefab steel structures?

11.Can prefab steel structures be designed to incorporate green building features?

12.How does the fire resistance of prefab steel structures compare to other building materials?

13.What is the assembly process for prefab steel structures?

1.What types of finishes are available for prefab steel structures?

Prefab steel structures can be finished in a variety of ways to suit the needs of the customer. The most common types of finishes are paint, powder coating, and galvanizing. Paint is the most common finish for prefab steel structures. It is available in a wide range of colors and can be applied to the steel in a variety of ways, including spray, brush, and roller. Paint is a great option for those who want to customize the look of their structure. Powder coating is another popular finish for prefab steel structures. It is a durable finish that is applied in a dry powder form and then cured in an oven. Powder coating is available in a wide range of colors and textures, and it is resistant to corrosion, fading, and chipping. Galvanizing is a process that involves coating the steel with a layer of zinc. This layer of zinc helps to protect the steel from corrosion and rust. Galvanizing is a great option for those who want a durable finish that will last for many years. No matter what type of finish you choose for your prefab steel structure, it is important to make sure that it is applied correctly and that it is maintained properly. This will ensure that your structure looks great and lasts for many years.

2.Can prefab steel structures be used for commercial and residential buildings?

Yes, prefab steel structures can be used for both commercial and residential buildings. Prefabricated steel structures are becoming increasingly popular due to their cost-effectiveness, durability, and versatility. Prefab steel structures are made from pre-engineered steel components that are manufactured in a factory and then shipped to the construction site. This allows for faster construction times and lower labor costs. Prefab steel structures are also incredibly strong and durable, making them ideal for both commercial and residential buildings. Steel is resistant to fire, wind, and other natural disasters, making it a great choice for buildings in areas prone to extreme weather. Steel is also non-combustible, making it a great choice for buildings in areas prone to earthquakes. Prefab steel structures are also incredibly versatile, allowing for a variety of design options. Steel can be used to create a wide range of shapes and sizes, making it easy to customize a building to fit the needs of the owner. Steel is also easy to modify, allowing for easy expansion or renovation of a building. Overall, prefab steel structures are an excellent choice for both commercial and residential buildings. They are cost-effective, durable, and versatile, making them a great choice for any building project.

3.Are there any limitations on interior layout for prefab steel structures?

Yes, there are some limitations on interior layout for prefab steel structures. The most common limitation is the size of the steel members used in the structure. Steel members are typically limited to a maximum length of 40 feet, which can limit the size of the interior space. Additionally, the shape of the steel members can limit the design of the interior layout. For example, curved steel members may be difficult to incorporate into a design. Another limitation is the weight of the steel members. Steel members are typically limited to a maximum weight of 40 pounds per square foot, which can limit the amount of interior space that can be created. Additionally, the weight of the steel members can affect the overall stability of the structure, so it is important to consider the weight of the steel members when designing the interior layout. Finally, the cost of the steel members can be a limitation. Steel members are typically more expensive than other materials, so it is important to consider the cost of the steel members when designing the interior layout. Overall, there are some limitations on interior layout for prefab steel structures. It is important to consider the size, shape, weight, and cost of the steel members when designing the interior layout.

4.How does the construction time of prefab steel structures compare to traditional buildings?

Prefab steel structures are typically constructed much faster than traditional buildings. This is because the components of the structure are pre-manufactured in a factory and then shipped to the construction site. This eliminates the need for on-site fabrication and reduces the amount of time needed for construction. Additionally, the components are designed to fit together quickly and easily, which further reduces the amount of time needed for construction. In comparison, traditional buildings require more time for construction due to the need for on-site fabrication and assembly. This can be a lengthy process, as each component must be cut, welded, and assembled on-site. Additionally, traditional buildings require more labor, as each component must be handled and installed by hand. Overall, prefab steel structures can be constructed much faster than traditional buildings. This is due to the fact that the components are pre-manufactured and designed to fit together quickly and easily. This reduces the amount of time needed for construction and allows for faster completion of the project.

5.Are there any limitations on the size of a prefab steel structure?

Yes, there are limitations on the size of a prefab steel structure. The size of a prefab steel structure is limited by the size of the steel components used in its construction. The size of the steel components is determined by the size of the steel mill that produces them. The size of the steel mill is limited by the size of the rolling mill, which is limited by the size of the furnace used to heat the steel. The size of the furnace is limited by the size of the blast furnace, which is limited by the size of the ore used to produce the steel. The size of the ore is limited by the size of the mine that produces it. Therefore, the size of a prefab steel structure is ultimately limited by the size of the ore mine that produces the steel components used in its construction.

6.What type of warranties are offered for prefab steel structures?

Prefab steel structures come with a variety of warranties depending on the manufacturer and the type of structure. Generally, warranties for prefab steel structures cover the structural integrity of the building, including the frame, roof, and walls. Most warranties also cover any defects in the materials used in the construction of the structure. The length of the warranty varies depending on the manufacturer, but most warranties last for at least 10 years. Some manufacturers offer warranties that last up to 25 years. In addition to the structural integrity of the building, some warranties also cover the paint and finish of the structure. This means that if the paint or finish begins to fade or chip, the manufacturer will replace it. Most warranties also cover any repairs or replacements that may be needed due to normal wear and tear. This includes any repairs that may be needed due to rust or corrosion. Finally, some warranties also cover any repairs or replacements that may be needed due to natural disasters, such as earthquakes, floods, or hurricanes. This is an important feature to consider if you live in an area that is prone to natural disasters. Overall, prefab steel structures come with a variety of warranties that cover the structural integrity of the building, the paint and finish, and any repairs or replacements that may be needed due to normal wear and tear or natural disasters. The length of the warranty varies depending on the manufacturer, but most warranties last for at least 10 years.

7.Can prefab steel structures be designed to withstand extreme weather conditions?

Yes, prefab steel structures can be designed to withstand extreme weather conditions. Steel is a strong and durable material that can withstand high winds, heavy snow, and other extreme weather conditions. Steel structures are also resistant to fire, rot, and pests, making them ideal for areas prone to extreme weather. Prefab steel structures can be designed to meet specific requirements for wind, snow, and seismic loads. Steel framing can be designed to meet local building codes and can be customized to meet specific needs. Steel framing can also be designed to be energy efficient, helping to reduce energy costs. Prefab steel structures can also be designed to be aesthetically pleasing. Steel framing can be designed to match the existing architecture of a building or to create a unique look. Steel framing can also be designed to be easily modified or expanded in the future. Prefab steel structures are a great option for areas prone to extreme weather conditions. Steel is a strong and durable material that can be designed to meet specific requirements and can be customized to meet specific needs. Steel framing can also be designed to be aesthetically pleasing and energy efficient.

8.Are prefab steel structures suitable for multi-story buildings?

Yes, prefab steel structures are suitable for multi-story buildings. Prefabricated steel structures are strong, durable, and cost-effective, making them an ideal choice for multi-story buildings. Steel is a strong and lightweight material, allowing for the construction of taller buildings with less material. Steel is also fire-resistant, making it a safe choice for multi-story buildings. Additionally, prefabricated steel structures are easy to assemble and can be erected quickly, reducing construction time and costs. Steel is also highly recyclable, making it an environmentally friendly choice. Prefabricated steel structures are also customizable, allowing for the design of buildings that meet specific needs. Finally, prefabricated steel structures are low-maintenance, requiring minimal upkeep and repairs. For these reasons, prefabricated steel structures are an excellent choice for multi-story buildings.

9.How does the weight of prefab steel structures impact transportation and installation?

The weight of prefab steel structures can have a significant impact on transportation and installation. Heavier structures require more robust transportation vehicles and equipment, which can increase the cost of transportation. Additionally, heavier structures can require more personnel to install, which can also increase the cost of installation. The weight of prefab steel structures can also affect the installation process. Heavier structures require more time and effort to install, as they must be lifted and placed into position. This can increase the risk of injury to personnel, as well as the risk of damage to the structure. Additionally, heavier structures can require more specialized equipment to install, which can increase the cost of installation. Finally, the weight of prefab steel structures can also affect the foundation requirements. Heavier structures require stronger foundations to support them, which can increase the cost of the foundation. Additionally, heavier structures can require more specialized equipment to install the foundation, which can also increase the cost of installation. Overall, the weight of prefab steel structures can have a significant impact on transportation and installation. Heavier structures require more robust transportation vehicles and equipment, as well as more personnel and specialized equipment to install. Additionally, heavier structures can require stronger foundations, which can increase the cost of installation.

10.Are there any size restrictions for transportation and delivery of prefab steel structures?

Yes, there are size restrictions for transportation and delivery of prefab steel structures. The size of the structure is limited by the size of the truck or trailer that is used to transport it. The maximum size of a structure that can be transported is typically determined by the size of the truck or trailer, the size of the load, and the weight of the structure. The size of the structure also affects the cost of transportation and delivery. Generally, larger structures require larger trucks and trailers, which can increase the cost of transportation and delivery. Additionally, the size of the structure can affect the route that the truck or trailer must take, which can also increase the cost of transportation and delivery. In some cases, the size of the structure may also require special permits or additional fees for transportation and delivery.

11.Can prefab steel structures be designed to incorporate green building features?

Yes, prefab steel structures can be designed to incorporate green building features. Steel is a highly recyclable material, making it an ideal choice for green building projects. Steel is also a strong and durable material, making it a great choice for structures that need to last for many years. Additionally, prefab steel structures can be designed to be energy efficient, with insulation and other features that help reduce energy consumption. Steel can also be used to create structures that are designed to take advantage of natural light and ventilation, reducing the need for artificial lighting and air conditioning. Finally, prefab steel structures can be designed to incorporate green building features such as rainwater harvesting, solar panels, and green roofs. All of these features can help reduce the environmental impact of a building and make it more sustainable.

12.How does the fire resistance of prefab steel structures compare to other building materials?

Prefab steel structures are highly fire resistant compared to other building materials. Steel is a non-combustible material, meaning it does not burn or contribute fuel to a fire. Steel also has a high melting point, which means it can withstand temperatures up to 1,500°F before it begins to deform. This makes it an ideal material for fire-resistant structures. In comparison, wood is a combustible material and can easily catch fire. It also has a low melting point, meaning it can easily be damaged by high temperatures. Other building materials such as concrete and brick are also combustible and can be damaged by high temperatures. Prefab steel structures are also more cost-effective than other building materials. Steel is a durable material that can last for decades with minimal maintenance. This means that prefab steel structures can provide long-term savings in terms of construction and maintenance costs. Overall, prefab steel structures are highly fire resistant and cost-effective compared to other building materials. They are an ideal choice for fire-resistant structures that require minimal maintenance and long-term savings.

13.What is the assembly process for prefab steel structures?

The assembly process for prefab steel structures typically involves the following steps: 1. Layout: The first step is to layout the steel structure on the ground. This includes marking the location of the columns, beams, and other components. 2. Foundation: The next step is to prepare the foundation for the steel structure. This includes digging the footings and pouring the concrete. 3. Erection: Once the foundation is ready, the steel components can be erected. This includes bolting the columns and beams together and attaching the other components. 4. Finishing: After the steel structure is erected, the finishing touches can be added. This includes painting, insulation, and other finishing touches. 5. Inspection: Once the steel structure is complete, it must be inspected to ensure it meets all safety and building codes. 6. Occupancy: After the inspection is complete, the structure can be occupied. Prefab steel structures are a great option for those looking for a quick and easy way to construct a building. With the right preparation and assembly process, these structures can be erected quickly and safely.