Prefabricated Steel Structure For Railway Station Platform

Review

Description

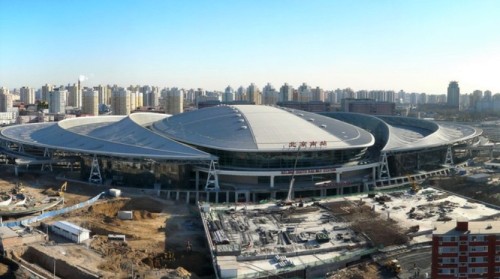

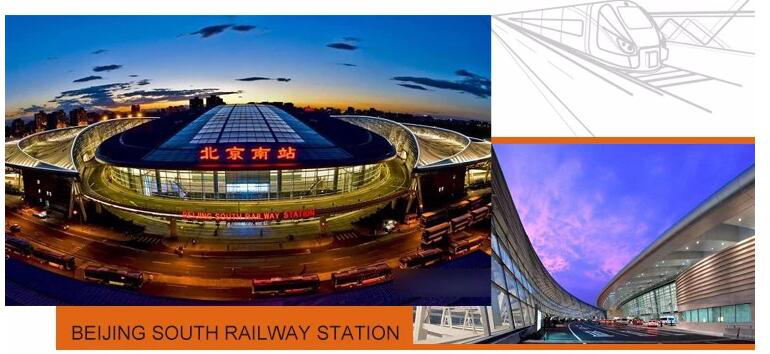

Project Name:Beijing South Railway Station

Project Info:

The station of Beijing South Railway Station is a hyperbolic dome with a high elevation of 40.0 meters and a height of 20.0 meters. The canopy on both sides is 31.5 meters high and the height of the cornice is 16.5 meters. The ground part has a long axis of 500 meters and a short axis of 350 meters; the underground part has a long axis of 397.1 meters and a short axis of 332.60 meters. The two wings of the ground along the long axis are transparent awnings for each three-span steel structure. The middle station is an elliptical tall building with two floors above ground and three underground floors.

From the top to the bottom, Beijing South Railway Station is: steel structure roof layer; ground elevated shelter floor; ground floor is the exit platform of the train station; the central base is the transfer area, the two sides are garage; the second floor is Metro Line 4; the third basement is Metro Line 14. The new Beijing South Railway Station, which combines beautiful shape and advanced functions, fully realizes three-dimensional traffic.

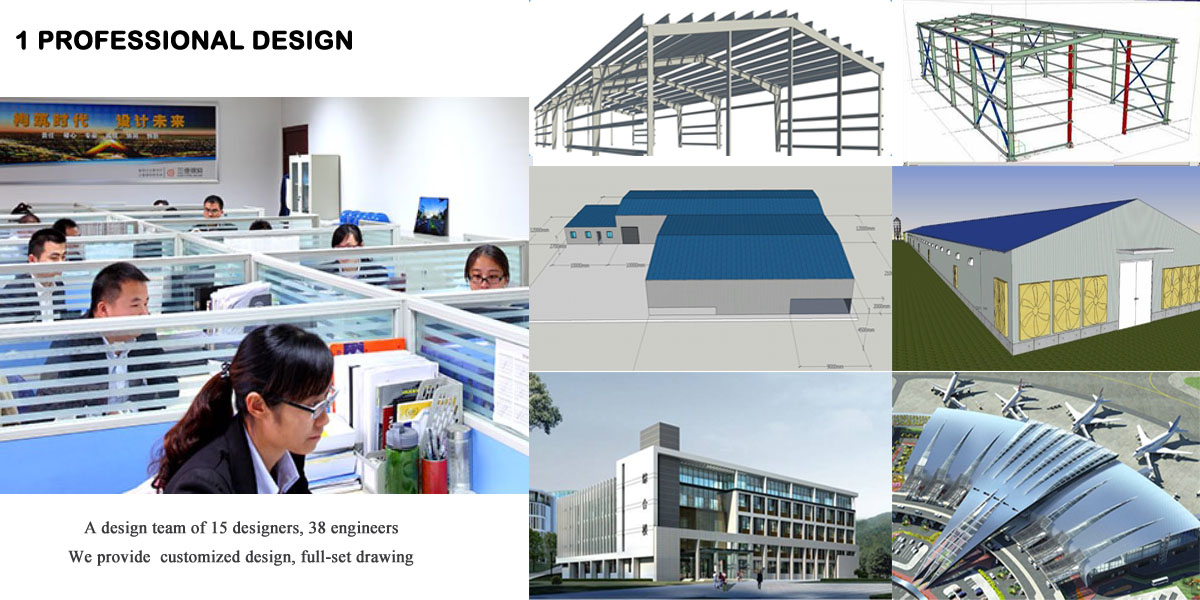

The feature of the steel structure train station:

1. Steel structure is lighter in weight

2. High reliability of prefab steel structure work

3. The steel is resistant to vibration and impact resistance

4. The degree of industrialization of steel structure manufacturing is relatively high

5. Prefabricated Steel structure can be assembled accurately and quickly

6. Large steel room interior space

7. Easy to make a sealed structure

8. Steel structure is easy to corrode

9. Steel structure can be recycled

10. Steel structure building has a short construction period