New Zealand steel structure workshop with 10 ton overhead crane

- Price

- US $30

- Model

- ZYM-06

- MOQ

- 500 square meter

Item specifics

- Name

- China Steel Structure Warehouse workshop with CE

- Key word

- China steel warehouse workshop manufacture with CE

- Material

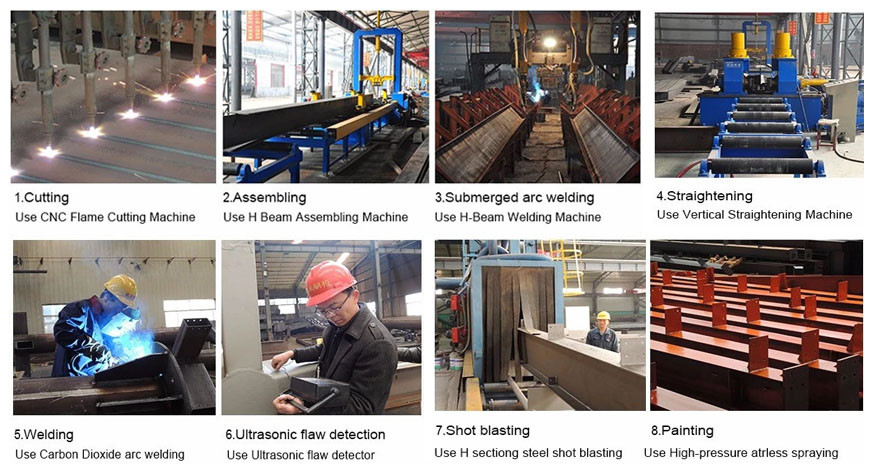

- Q235,Q345B,SS400,H type hot rolled steel

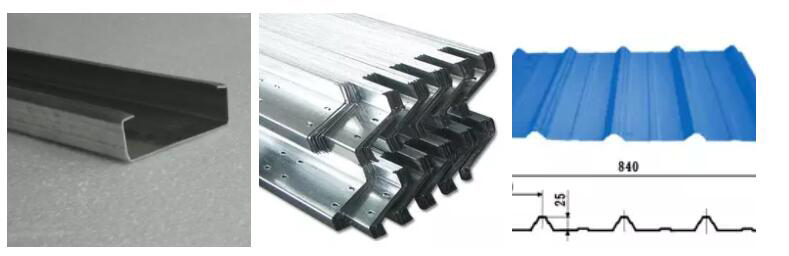

- roof of steel structure workshop

- Galvanized color sheet or sandwich panel

- wall of steel structure workshop

- Galvanized color sheet or sandwich panel

- steel structure workshop door and window

- Aluminium alloy and PVC

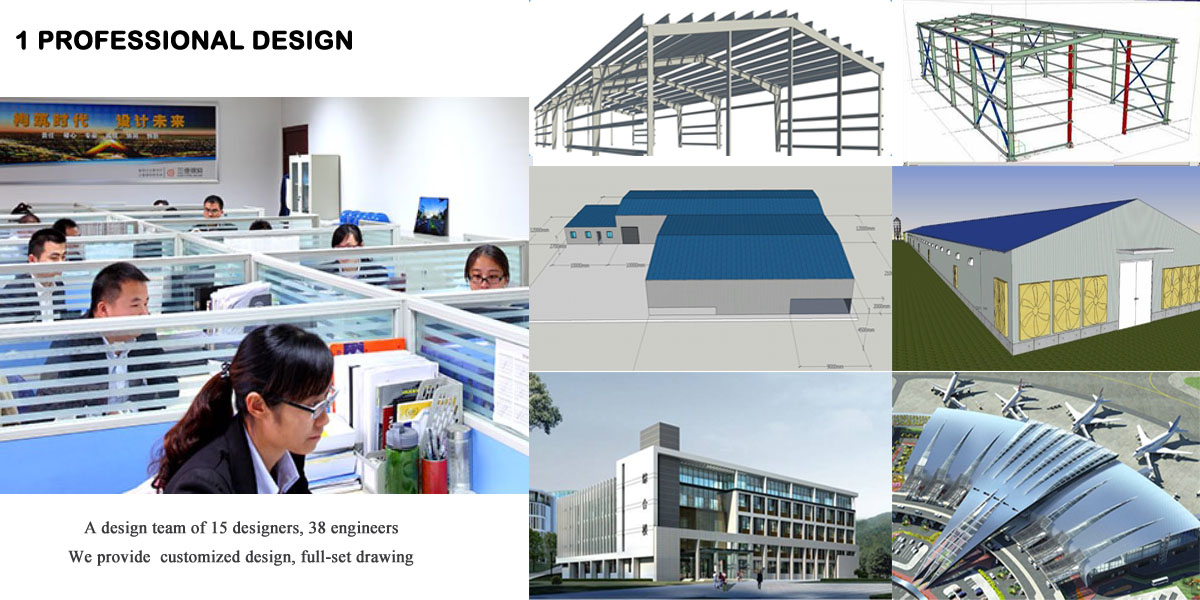

- Application

- workshop,warehouse,office,hotel,commerical,school

- Certification

- CE certification,ISO certification

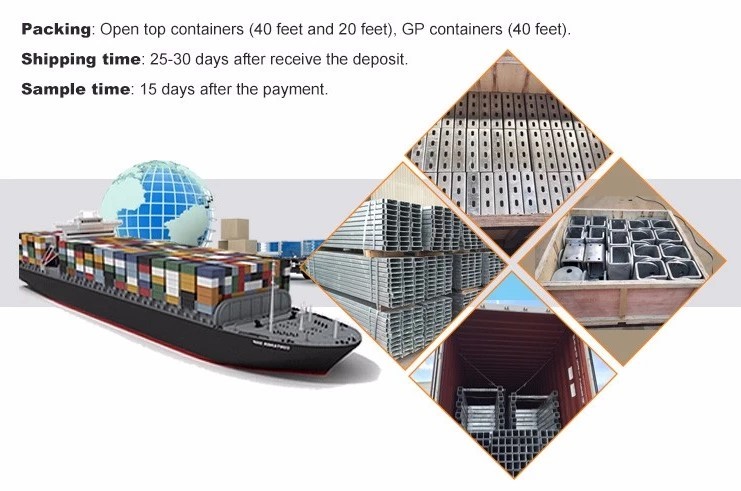

- delivery time

- 30 days after steel structure design confirmed

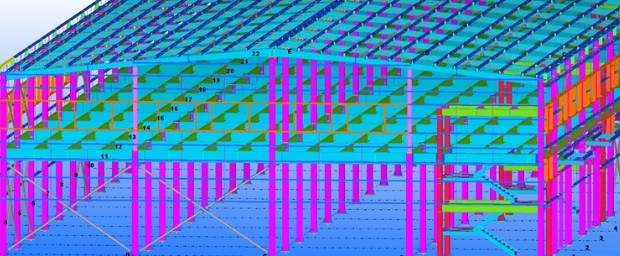

- steel structure design softwaree

- CAD,3D3S,3DMX,TEKLA

Review

Description

Characteristics of steel structure factory buildings include:

1. Light weight, high strength, and large span of steel structure buildings.

2. The construction period of steel structure buildings is short, which correspondingly reduces investment costs.

3. Steel structure buildings have poor fire resistance, are not corrosion-resistant, and should not be used in areas with low temperatures.

4. Steel structure buildings are easy to move and recycle without pollution.| prefab steel structure

Detail material informations are as follows:

Widely used: suitable for factories, warehouses, office buildings, sports venues, aircraft hangars, and more. Suitable for both single-story and large-span buildings, as well as for building multi-story or high-rise buildings.