China Steel structure manufacturing - Al Wakrah Stadium of Qatar appeared in Qatar World Cup

- Share

- publisher

- ZYM

- Issue Time

- Dec 9,2022

Summary

On the opening day of the World Cup,China steel structure is also in "another arena"

At 0:00 on November 21, Beijing time

The 2022 Qatar World Cup officially opens

Having undertaken the Beijing Winter Olympics in China

Construction contractors of sports venues for several important international events

On the opening day of the World Cup

China steel structure is also in "another arena"

Actively participate in the World Cup

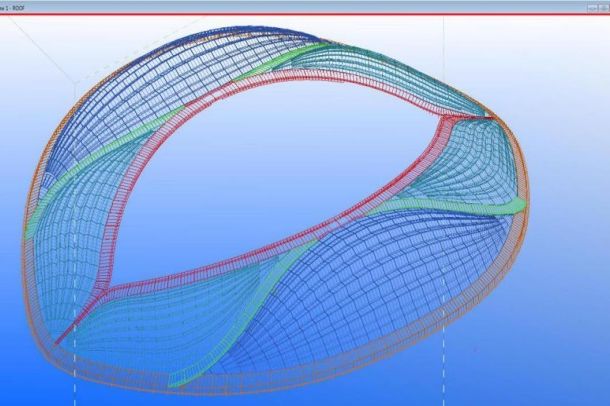

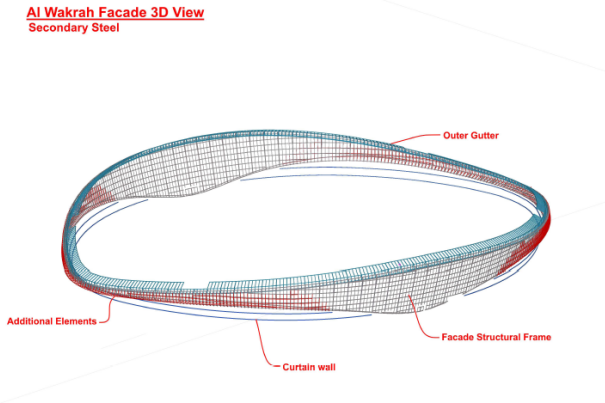

Inspired by local traditional culture and dhow

Design key marine elements

The roof is designed as an inverted sloop hull

The facade is tapered and inclined outwards

Large cantilevered eaves covered with metal cladding

The streamline white outline of the court is similar to a sail blown by the wind

With removable modular seat design, there are about 40000 seats

The company undertakes the processing, manufacturing and FOB delivery of some steel structures of the project

Fine management and strict control

The project components have strict quality requirements and high acceptance standards

Construction materials,Thin wall straight seam pipe (80 * 5-200 * 8)

The part plates are mainly 5-25mm thin plates,Material S355JR

European standard or American standard shall be adopted for welding

NDT shall be carried out according to American standard AWS D1.1

Small project components and many parts

And there are many space warp components

Including 23086 components

100 parts per ton of component

90% of the member end plate is not perpendicular to the member,Square tube cannot be sawed by numerical control cutting machine,Manual cutting only

A large number of support plates with different spatial angles

Height between 300-1000mm

It is difficult to weld components

Main welds and rib plate welds of steel members of the project

Adopt penetration weld

Large welding amount and easy deformation

The fabrication plant specially sets up a project welding team

Carry out targeted training and examination selection for welders

Refine the welding sequence of welds

Specify welding direction and welding process parameters

Take anti deformation measures such as fixing and baking in advance

Finally ensure that the audit and inspection pass smoothly

For further information feel free to contact us.

E-mail: sales@zyminfra.com