Heavy Steel Structure Building

- Share

What is the heavy steel structure building?

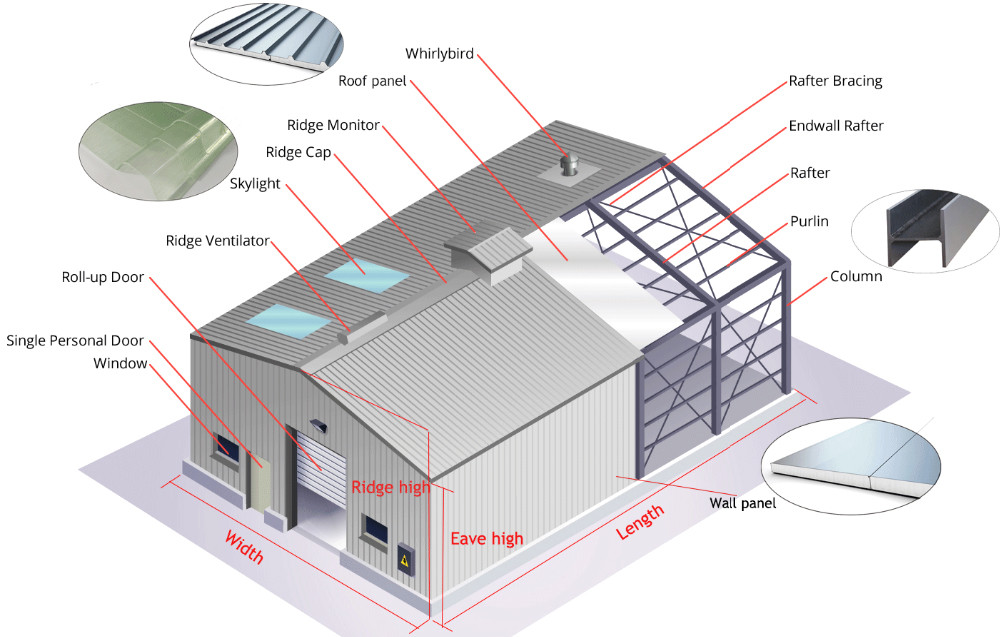

Steel structure building is a type of construction with load-bearing structure made of construction steel,beams, columns, trusses and other components .It is usually made of shaped steel and steel plates constitute a load-bearing structure. It forms a whole steel building system with the maintenance system such as roof panel, floor panel and wall panel.

Heavy steel structures usually refer to hot-rolled angle steel, channel steel, I-beam, H-beam and steel pipe. A building that forms a load-bearing structure from its components is called a heavy-duty steel structure building. In addition, thin-walled steels, such as L-shaped, U-shaped, Z-shaped and tubular-shaped, which are formed by cold-rolling of steel sheets, are rolled or unwound, and assembled together with the parts members which are made of small steel materials such as angle steel and steel bar, generally referred to as light steel construction.

Heavy steel structure building main parts included H-shaped steel, color profiled steel plate, C-type, Z-shaped purlins, floor-supporting composite panels,all the wall and roof maintenance system .

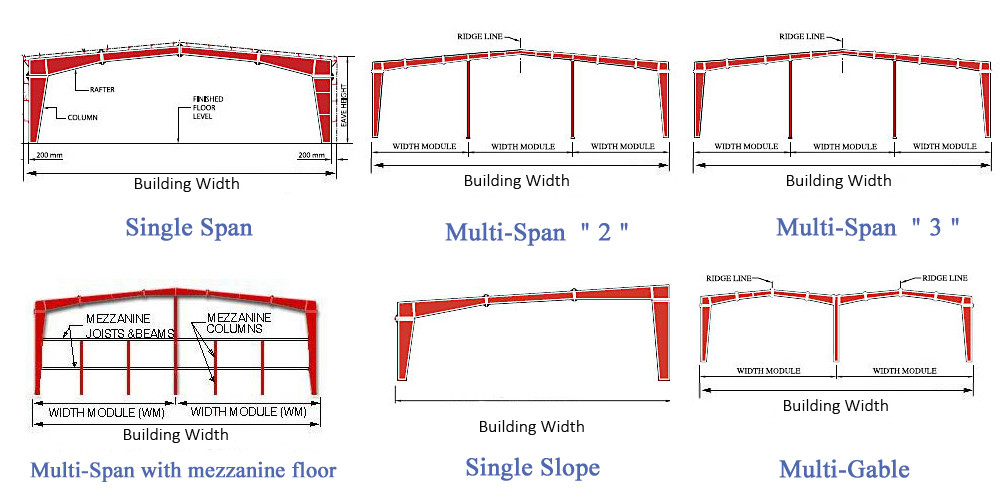

The heavy Steel structure is divided into different design types

The portal frame is a traditional structural system. The upper main frame of this type of structure includes steel beams, columns, supports, purlins, tie rods, gable skeletons. The steel structure of the portal frame light-duty house has the characteristics of simple force, clear transmission path, quick component production, easy factory processing and short construction period. General industrial plant, workshop, warehouse, poultry house, small garage, hangar, offices are widely used in this type.

2. Frame steel structure

Pure frame, Central support frame, Eccentric support frame, frame tube (tight column frame); multi-layer steel structure plant with load-bearing requirements, school, hospital, shopping mall, multi-storey office, multi-storey residential, municipal infrastructure construction adopt frame steel structure .

3. Grid steel structure - grid, net shell

Because the grid, shell structure can adapt to different spans, different plane shapes, different support conditions, different functional needs of the building, not only small and medium span industrial and civil buildings have applications, Moreover, it is widely used in large-scale stadiums, exhibition halls, town halls, theaters, stations, hangars, factories, warehouses and other buildings.

Features of heavy steel structure buildings:

1.The steel structure building system has the advantages of light weight, factory manufacturing, quick installation, short construction period, fast investment recovery and less environmental pollution. Compared with concrete and wood, the ratio of density to yield strength is relatively low. Therefore, under the same stress conditions, the steel structure has a small cross section, light weight, easy transportation and installation, and is suitable for large span, high height, and heavy bearing capacity. So the steel frame is more "quick, easy and light".

2.Good wind resistance

The steel structure has light weight, high strength, good overall rigidity and strong deformation ability. The building's own weight is only one-fifth of the brick-concrete structure, which can withstand hurricanes of 70 meters per second, so that life and property can be effectively protected.

3.Good seismic performance

steel structure material is toughness, good plasticity, uniform material and high structural reliability.Suitable for impact and dynamic loads, with good seismic performance. The internal structure of the steel is uniform and close to the isotropic homogeneous body. The actual working performance of the steel structure is in line with the calculation theory. Therefore, the steel structure has high reliability.

4. High degree of mechanization in steel structure manufacturing and installation.

Steel structural members are easy to manufacture at the factory and assembled on site. The mechanized manufacturing of steel structural members in the factory has high precision, high production efficiency, fast assembly speed and short construction period. Steel structure is the most industrialized structure.

5, Sealing performance is good

Since the welded structure can be completely sealed, it can be made into a high-pressure container with good airtightness and water tightness, a large oil pool, a pressure pipe and the like.

6,Steel structure is heat resistant and not fire resistant

When the temperature is below 150 ° C, the properties of the steel change little. Therefore, the steel structure is suitable for use in a hot workshop, but when the surface of the structure is subjected to heat radiation of about 150 ° C, it is protected by a heat shield. When the temperature is between 300 ° C and 400 ° C, the strength and elastic modulus of the steel are significantly reduced. When the temperature is around 600 ° C, the strength of the steel tends to zero. In buildings with special fire protection requirements, the steel structure must be protected with refractory materials to increase the fire rating.