prefabricated structure workshop

- Model

- ZYM1

Item specifics

- Name

- Indonesia steel structure warehouse workshop

- Key word

- Indonesia steel structure workshop with office

- Design

- 3D max,CAD for steel structure frame

- Material

- Q235,Q345B,SS400 steel structure

- Foof

- Galvanized color sheet or sandwich panel

- Wall

- Galvanized sheet for steel structure workshop

- Place of project

- Indonesia steel structure workshop and warehouse

- Delivery time

- 30 days after steel structure drawing confirmation

- Package

- Steel structure frame pallet for 40HQ container

- Application

- workshop,warehouse,office,commercial bulding,shop

Review

Description

ZhengYuanming Construction Engineering Co., Ltd. who has been becoming the leading company of Steel Building Construction & Steel Fabrication products. Qingdao ZhengYuanming is one-stop manufacturer of light frame steel structure warehouse,prefabricated steel frame structure workshop,modular steel large span workshop,steel structure installation for workshop,steel structure building design,Prefab Light Steel Structure Warehouse Shed,workshop building construction,windows and doors, fasteners with well-equipped testing facilities and strong technical support. our products have entered into many foreign countries like the JordanThe ZhengYuanMingTeam Group is a leading international steel structure manufacturers with 20+ years of group experience in prefabricated steel material production,+126,000㎡steel structure building construction in service.

| Product name |

prefabricated structure workshop |

|---|---|

| Brand Name |

ZYM |

| Model Number |

STEEL - 01 |

| Material |

Steel column base,Pressure plate etc |

| Brand |

ZYM prefabricated structure workshop Manufacturer |

| Tolerance |

±1% |

| Keyword |

made real prefab steel structure workshop,steel structure building makers,architecture steel structure building,prefab workshop steel building,light steel structure warehouse with office |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| Application |

Light Steel Structure Warehouse,steel frame structure building,steel frame agricultural building |

| Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Samoa,Colombia,Philippines,Denmark |

ZYM One-Stop Steel Structure Material

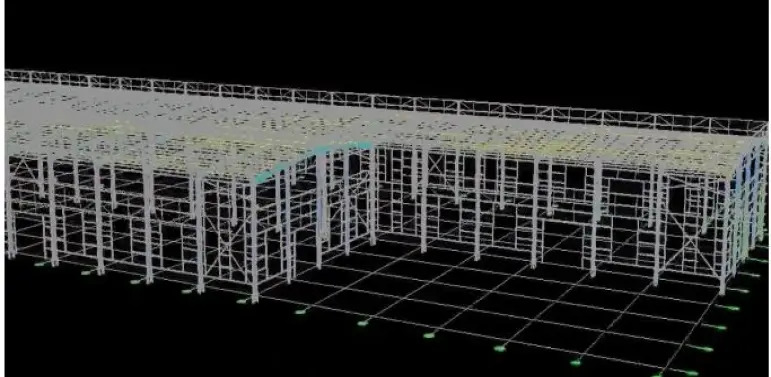

Structural form: Three story steel structure frame engineering

Project Name: prefabricated structure workshopRecently, multiple steel structure projects undertaken by our company are steadily advancing and continuously making new progress.The company's project department and steel structure processing plant seize the golden period of construction and ensure the perfect performance of the project.prefabricated structure workshop services FAQs GuideAre you looking for a quick review guide about prefabricated structure workshopservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding prefabricated structure workshop services.Let’s continue!

2.What type of foundation is required for a steel structure building?

3.What is Steel Structure and How Does it Differ from Traditional Construction?

4.How does the construction time of a steel structure building compare to traditional methods?

5.What kind of company you are?

6.Can prefabricated structure workshop be designed to be eco-friendly?

7.prefabricated structure workshop What factors contribute to the strength and stability of a steel structure building?

8.How does the weight of a steel structure building affect site preparation and construction?

9.Do you offer service for installation?

10.Can prefabricated structure workshop be relocated or disassembled?

11.prefabricated structure workshop What is the average lifespan of a steel structure building?

12.What are the advantages of prefabricated prefabricated structure workshop?

13.Can prefabricated structure workshop be customized to fit specific design requirements?

1.What is the typical cost of maintenance for a steel structure building?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system. The cost of maintenance for a steel structure building can vary greatly depending on the size and complexity of the building. Generally, the cost of maintenance for a steel structure building is between 1-2% of the total cost of the building. This cost includes regular inspections, painting, and repairs.

2.What type of foundation is required for a steel structure building?

We are a professional prefabricated structure workshop company dedicated to providing high quality products and services. The foundation type required for a steel structure building will depend on the size and type of building, as well as the soil conditions of the site. Generally, steel structure buildings require a concrete slab-on-grade foundation, a shallow foundation, or a deep foundation.

3.What is Steel Structure and How Does it Differ from Traditional Construction?

We should perform well in market competition, and the prices of prefabricated structure workshop products have a great competitive advantage. Steel structure is a type of construction that uses steel as the primary structural element. It is typically used for large buildings and bridges, and is becoming increasingly popular for residential and commercial construction. Steel structure differs from traditional construction in that it uses steel components instead of wood, concrete, or other materials. Steel structure is lighter, stronger, and more durable than traditional construction, and is also more cost-effective. Steel structure also requires less maintenance and is more resistant to fire, wind, and other natural disasters.

4.How does the construction time of a steel structure building compare to traditional methods?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Steel structure buildings typically take less time to construct than traditional methods. Steel structures can be erected in a fraction of the time it takes to build a traditional building, often in as little as half the time. Steel structures are also more cost-effective, as they require fewer materials and labor to construct. Additionally, steel structures are more durable and require less maintenance over time.

5.What kind of company you are?

ZYM Team Group focus on creating and protecting value. We offer the full range of steel structure products, from steel material to highly engineered building systems, as well as accessories. Our full production line offers high-quality products at competitive prices. We pay attention to every little detail to ensure our steel structure more perfect. ZYM has three modern base centers, one center is responsible for design and R&D, one center handles production ,one center is for the sales and service.The group maintains production facilities for high-quality prefabricated steel,steel structure with an annual output of 50,000-60,000 tons of steel structure.

6.Can prefabricated structure workshop be designed to be eco-friendly?

We have a professional team that is committed to the innovation and development of prefabricated structure workshop. Yes, steel structure buildings can be designed to be eco-friendly. Steel is a highly recyclable material, so it can be reused in the construction of new buildings. Additionally, steel is a very strong material, so it can be used to create buildings that are more energy efficient and require less energy to heat and cool. Steel can also be insulated with materials such as recycled denim or other sustainable materials to further reduce energy consumption.

7.prefabricated structure workshop What factors contribute to the strength and stability of a steel structure building?

We have broad development space in domestic and foreign markets. prefabricated structure workshop have great advantages in terms of price, quality, and delivery date. 1. Design: The design of a steel structure building is critical to its strength and stability. The design should take into account the loads that the building will be subjected to, such as wind, snow, and seismic forces. 2. Connections: The connections between the steel members are also important for the strength and stability of the building. The connections should be designed to be strong and secure, and should be able to resist the forces that the building will be subjected to. 3. Materials: The materials used in the construction of the steel structure building should be of high quality and should be able to withstand the loads that the building will be subjected to. 4. Foundation: The foundation of the building should be designed to be strong and stable, and should be able to support the weight of the building. 5. Maintenance: Regular maintenance of the steel structure building is important to ensure its strength and stability. This includes inspecting the building for any signs of corrosion or damage, and making any necessary repairs.

8.How does the weight of a steel structure building affect site preparation and construction?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of prefabricated structure workshop products. The weight of a steel structure building affects site preparation and construction in several ways. First, the weight of the steel structure must be taken into account when designing the foundation and other structural elements. The foundation must be designed to support the weight of the steel structure, and the soil must be able to bear the load. Additionally, the weight of the steel structure must be taken into account when designing the crane and other lifting equipment used to move the steel structure into place. Finally, the weight of the steel structure must be taken into account when designing the temporary bracing and other support systems used during construction.

9.Do you offer service for installation?

We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step. We also could send the engineer to your local to help you if neede.

10.Can prefabricated structure workshop be relocated or disassembled?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services. Yes, steel structure buildings can be relocated or disassembled. Steel structures are designed to be easily dismantled and reassembled, making them ideal for relocation. Steel structures can be disassembled and reassembled quickly and easily, making them a great option for businesses that need to move or expand.

11.prefabricated structure workshop What is the average lifespan of a steel structure building?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. The average lifespan of a steel structure building is between 50 and 100 years, depending on the quality of the materials used and the maintenance of the building.

12.What are the advantages of prefabricated prefabricated structure workshop?

We continue to invest in research and development and continue to launch innovative products. 1. Cost-Effective: Prefabricated steel structures are cost-effective and can be built quickly, saving time and money. 2. Durability: Steel is a strong and durable material that can withstand harsh weather conditions and is resistant to fire, termites, and other pests. 3. Flexibility: Prefabricated steel structures can be easily modified and adapted to fit any design or purpose. 4. Eco-Friendly: Steel is a recyclable material, making it an environmentally friendly choice for construction. 5. Low Maintenance: Steel structures require minimal maintenance and are easy to clean and repair. 6. Versatility: Prefabricated steel structures can be used for a variety of applications, from residential to commercial and industrial.

13.Can prefabricated structure workshop be customized to fit specific design requirements?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market. Yes, steel structure buildings can be customized to fit specific design requirements. Steel structure buildings are highly customizable and can be designed to meet the exact needs of the customer. Steel structure buildings can be designed to fit any size, shape, or style, and can be customized with a variety of features such as windows, doors, insulation, and more.