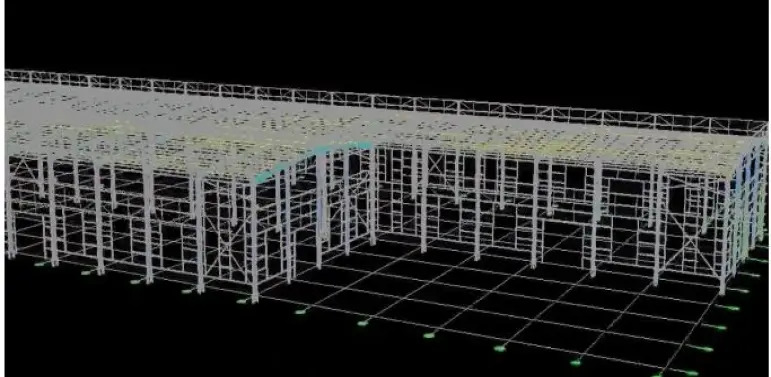

prefabricated big steel structure warehouse

- Model

- ZYM1

Item specifics

- Name

- Indonesia steel structure warehouse workshop

- Key word

- Indonesia steel structure workshop with office

- Design

- 3D max,CAD for steel structure frame

- Material

- Q235,Q345B,SS400 steel structure

- Foof

- Galvanized color sheet or sandwich panel

- Wall

- Galvanized sheet for steel structure workshop

- Place of project

- Indonesia steel structure workshop and warehouse

- Delivery time

- 30 days after steel structure drawing confirmation

- Package

- Steel structure frame pallet for 40HQ container

- Application

- workshop,warehouse,office,commercial bulding,shop

Review

Description

ZhengYuanming Construction Engineering Co., Ltd. specializes in the design, manufacturing and installation of various types of steel structure buildings. The factory building area is about 50,000 square meters. We produce all steel structure building related materials, such as C/Z/H steel, fireproof and insulated sandwich panels, PPGI steel plates and coils, waterproofing panels and decorative parts. Our workshop has many advanced equipments.We specialize in steel structure multi-story buildings, metal pre-engineered prefab workshop,Workshop Recyclable Steel Structure,steel framed building with brick cladding,high quality workshop building plans,Prefab Steel Structure Warehouse Shed,tow storey steel structure workshop,china steel building for car showroom and workshop,factory supply steel structure workshop,large span real estate steel frame workshop,High quality steel structure warehouse . Our engineering team is an experienced and efficient team. Understanding customers' needs, giving accurate designs, and saving customers' time and money are our basic responsibilities. We have a complete quality control system. From raw materials to finished products, our QC personnel will take a 100% serious attitude to ensure that each product project is produced exactly as designed.Our products have been exported to Russia, the United States, Australia, Latvia, etc. Improving product quality and developing new customers are always our goals! We also welcome OEM and ODM orders.

| Product name |

prefabricated big steel structure warehouse |

|---|---|

| Brand Name |

ZYM |

| Model Number |

STEEL - 01 |

| Material |

Anti-rust paint,steel plate,and stainless steel etc |

| Brand |

ZYM prefabricated big steel structure warehouse Manufacturer |

| Tolerance |

±1% |

| Keyword |

Prefab Steel Structure Workshop Series,galvanized steel workshop,demount light steel structur workshop |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| Application |

storage steel structure warehouse,Metal Sheet Steel Structure Warehouse,prefab high-strength steel structure warehouse,steel structure barns |

| Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Seychelles,Israel,Poland,South Africa |

ZYM One-Stop Steel Structure Material

specially used for steel structure factory, color steel plate V840 and 950 color steel plate for warehouse

ZYM provide the integrated solutions for our clients . After the steel structure design , we arrange the steel metal pre-engineered prefab workshop,Workshop Recyclable Steel Structure,steel framed building with brick cladding,high quality workshop building plans,Prefab Steel Structure Warehouse Shed,tow storey steel structure workshop,china steel building for car showroom and workshop,factory supply steel structure workshop,large span real estate steel frame workshop,High quality steel structure warehouse . In the process , we provide the best quality steel structure and the quality is approved prefabricated big steel structure warehouse services FAQs GuideAre you looking for a quick review guide about prefabricated big steel structure warehouseservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding prefabricated big steel structure warehouse services.Let’s continue!

2.prefabricated big steel structure warehouse What is the average lifespan of a steel structure building?

3.What safety precautions should be taken when working on a steel structure building?

4.Are prefabricated big steel structure warehouse environmentally friendly?

5.How does the weight of a steel structure building affect site preparation and construction?

6.What are the design considerations for a prefabricated big steel structure warehouse?

7.Can prefabricated big steel structure warehouse be relocated or disassembled?

8.What type of steel is used in the construction of prefabricated big steel structure warehouse?

9.How does the construction time of a steel structure building compare to traditional methods?

10.Can prefabricated big steel structure warehouse be designed to be eco-friendly?

11.What design options are available for the exterior aesthetics of a prefabricated big steel structure warehouse?

12.What type of maintenance is required for prefabricated big steel structure warehouse?

1.What kind of company you are?

ZYM Team Group focus on creating and protecting value. We offer the full range of steel structure products, from steel material to highly engineered building systems, as well as accessories. Our full production line offers high-quality products at competitive prices. We pay attention to every little detail to ensure our steel structure more perfect. ZYM has three modern base centers, one center is responsible for design and R&D, one center handles production ,one center is for the sales and service.The group maintains production facilities for high-quality prefabricated steel,steel structure with an annual output of 50,000-60,000 tons of steel structure.

2.prefabricated big steel structure warehouse What is the average lifespan of a steel structure building?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. The average lifespan of a steel structure building is between 50 and 100 years, depending on the quality of the materials used and the maintenance of the building.

3.What safety precautions should be taken when working on a steel structure building?

We have established a good reputation and reliable partnerships within the prefabricated big steel structure warehouse industry. 1. Wear appropriate safety gear, such as hard hats, safety glasses, and steel-toed boots. 2. Use appropriate fall protection equipment, such as safety harnesses and lanyards. 3. Use appropriate tools for the job, such as wrenches, hammers, and saws. 4. Secure all tools and materials to prevent them from falling. 5. Follow all safety protocols and procedures. 6. Inspect the structure for any signs of damage or wear before beginning work. 7. Be aware of your surroundings and watch out for any potential hazards. 8. Use appropriate lifting techniques to prevent injury. 9. Use appropriate scaffolding and ladders to reach higher areas. 10. Disconnect all power sources before beginning work.

4.Are prefabricated big steel structure warehouse environmentally friendly?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers. Yes, steel structure buildings are environmentally friendly. Steel is a recyclable material, so steel structure buildings can be disassembled and the steel reused. Steel is also a durable material, so steel structure buildings can last for decades with minimal maintenance. Steel structure buildings also require less energy to construct than other types of buildings, making them more energy efficient.

5.How does the weight of a steel structure building affect site preparation and construction?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of prefabricated big steel structure warehouse products. The weight of a steel structure building affects site preparation and construction in several ways. First, the weight of the steel structure must be taken into account when designing the foundation and other structural elements. The foundation must be designed to support the weight of the steel structure, and the soil must be able to bear the load. Additionally, the weight of the steel structure must be taken into account when designing the crane and other lifting equipment used to move the steel structure into place. Finally, the weight of the steel structure must be taken into account when designing the temporary bracing and other support systems used during construction.

6.What are the design considerations for a prefabricated big steel structure warehouse?

We have a wide range of prefabricated big steel structure warehouse customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include Malaysia. 1. Structural Design: The structural design of a steel structure building should consider the building’s load-bearing capacity, the type of steel used, the size and shape of the steel members, and the connections between the members. 2. Architectural Design: The architectural design of a steel structure building should consider the building’s aesthetic appeal, the type of cladding used, the size and shape of the building, and the overall layout of the building. 3. Fire Protection: The fire protection of a steel structure building should consider the type of fire protection system used, the type of steel used, and the fire resistance rating of the steel. 4. Environmental Considerations: The environmental considerations of a steel structure building should consider the type of steel used, the type of insulation used, and the energy efficiency of the building. 5. Maintenance: The maintenance of a steel structure building should consider the type of steel used, the type of coating used, and the maintenance schedule for the building.

7.Can prefabricated big steel structure warehouse be relocated or disassembled?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services. Yes, steel structure buildings can be relocated or disassembled. Steel structures are designed to be easily dismantled and reassembled, making them ideal for relocation. Steel structures can be disassembled and reassembled quickly and easily, making them a great option for businesses that need to move or expand.

8.What type of steel is used in the construction of prefabricated big steel structure warehouse?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail. The most common type of steel used in the construction of steel structure buildings is mild steel, also known as low carbon steel. Other types of steel that may be used include high-strength steel, stainless steel, and weathering steel.

9.How does the construction time of a steel structure building compare to traditional methods?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Steel structure buildings typically take less time to construct than traditional methods. Steel structures can be erected in a fraction of the time it takes to build a traditional building, often in as little as half the time. Steel structures are also more cost-effective, as they require fewer materials and labor to construct. Additionally, steel structures are more durable and require less maintenance over time.

10.Can prefabricated big steel structure warehouse be designed to be eco-friendly?

We have a professional team that is committed to the innovation and development of prefabricated big steel structure warehouse. Yes, steel structure buildings can be designed to be eco-friendly. Steel is a highly recyclable material, so it can be reused in the construction of new buildings. Additionally, steel is a very strong material, so it can be used to create buildings that are more energy efficient and require less energy to heat and cool. Steel can also be insulated with materials such as recycled denim or other sustainable materials to further reduce energy consumption.

11.What design options are available for the exterior aesthetics of a prefabricated big steel structure warehouse?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced prefabricated big steel structure warehouse products. 1. Paint: Steel structures can be painted in a variety of colors to match the surrounding environment. 2. Siding: Steel structures can be clad in a variety of siding materials such as brick, stone, stucco, wood, or metal. 3. Windows and Doors: Steel structures can be fitted with a variety of windows and doors to match the desired aesthetic. 4. Roofing: Steel structures can be fitted with a variety of roofing materials such as metal, shingles, or tiles. 5. Lighting: Steel structures can be fitted with a variety of lighting fixtures to enhance the exterior aesthetic. 6. Awnings: Steel structures can be fitted with awnings to provide shade and protection from the elements.

12.What type of maintenance is required for prefabricated big steel structure warehouse?

We enjoy high authority and influence in the industry and continue to innovate products and service models. Steel structure buildings require regular maintenance to ensure they remain structurally sound and safe. This includes inspecting the building for signs of corrosion, checking for loose or damaged fasteners, inspecting the roof and walls for signs of wear, and inspecting the foundation for signs of settlement or cracking. Additionally, it is important to regularly inspect the building for signs of pests or other infestations, and to check for any signs of water damage.