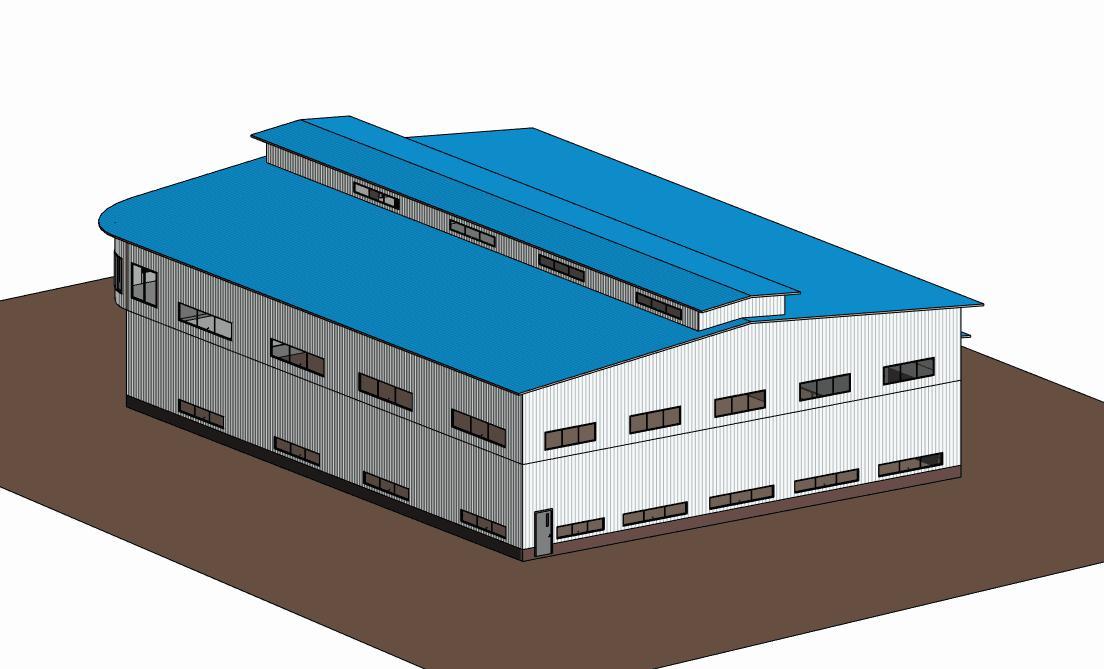

Indonesia prefab steel structure warehouse double storey shed

- Model

- ZYM1

Item specifics

- warehouse roof sheet

- sea blue red

- workshop wall panel

- galvanized sheet pvc panel

- anticorrosive

- Antirust paint, epoxy zinc rich paint,Galvanized

- Design

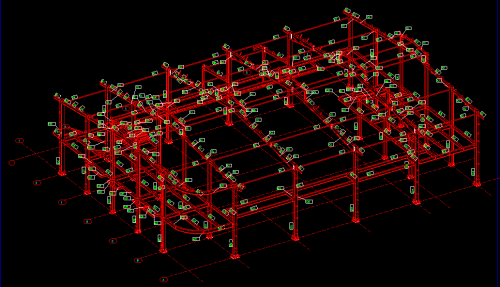

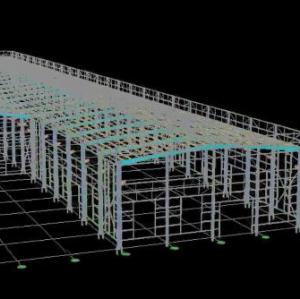

- 3D Modular Design Steel Structure Warehouse

- software

- PKPM 、3D3S , PKPM

Review

Description

How to build a double story steel structure workshop with warheouse and office?

-Indonesia steel structure workshop project

Indonesia Mr Wandi contacted us to build a steel structure workshop with office and warehouse ,their company listed all the detail requirements of the proejcts,we make the drawing and listed all the materials for clients confirmation.

Ⅰ-Communication And Design

Specificaitons as follows:

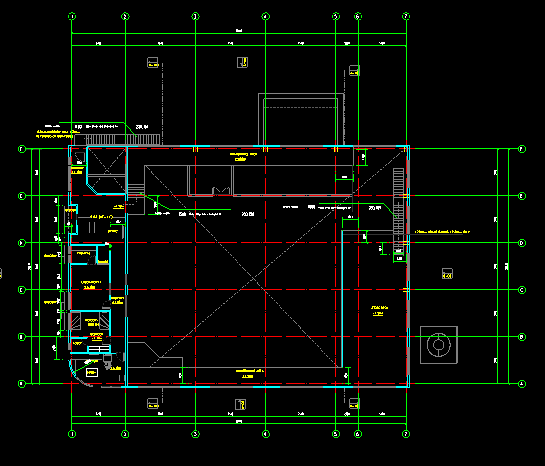

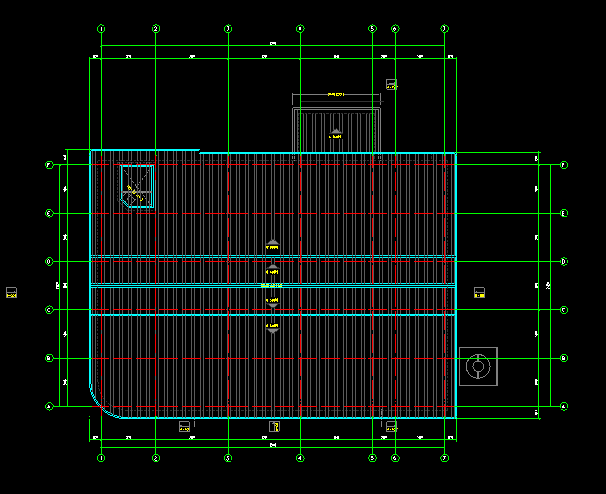

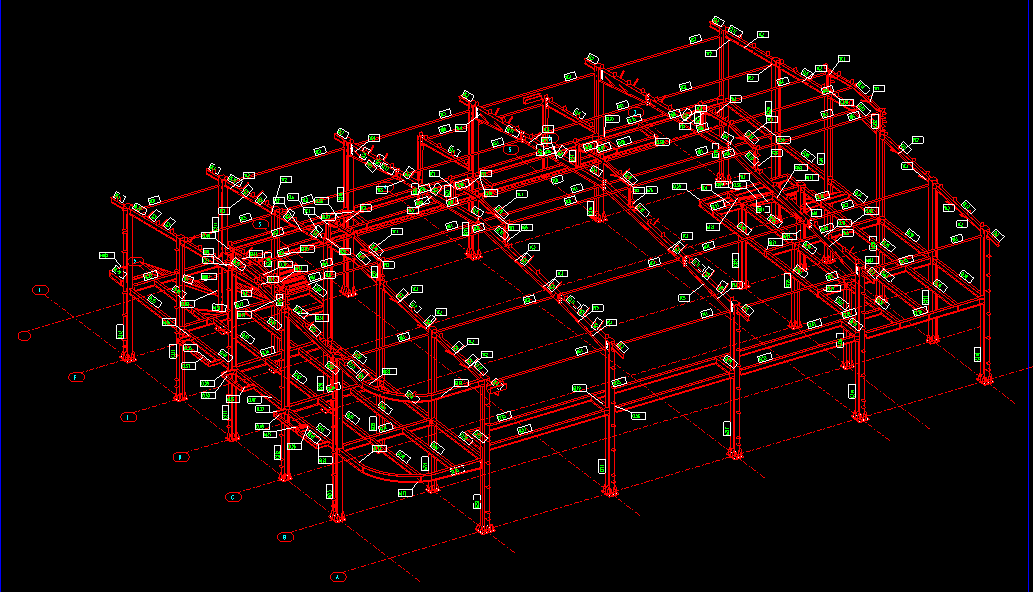

a) Provide all the structural steel required for the building which includes foundation anchor bolts, columns, Beams, Roof Beams, Roofing sheets, bolts…etc. (All the steel structure should be epoxy painted).

b) Provide all the Cladding material for the building wall including all required framing for fixing of cladding.

c) Provide all steel structure mezzanine decking materials.

d) Provide all staircases mentioned in the drawing. Tread: 280mm, Height: 167mm.

e) Provide hand railings (staircase) and railings (decks) as per shown in the drawings.

f) Provide steel structure building Roofing Sheets including purling, heat insulation material and all required material for fixing of Roof.

g) Careful procedures for steel structure frame erection drawings giving importance to the given drawings.

h) Provide all railings including staircase railings in Stainless steel

i) Provide structural steel parts drawings and structural calculations ) steel Foundation and any other required civil work related designs should be provided.

k) Foundation of the steel structure building should be constrained within the build area and should not extend outside.

l) The steel structure warehouse Load bearing capacity of the soil should be 150 kn/m2.

m) Foundation depth should be 2 meter

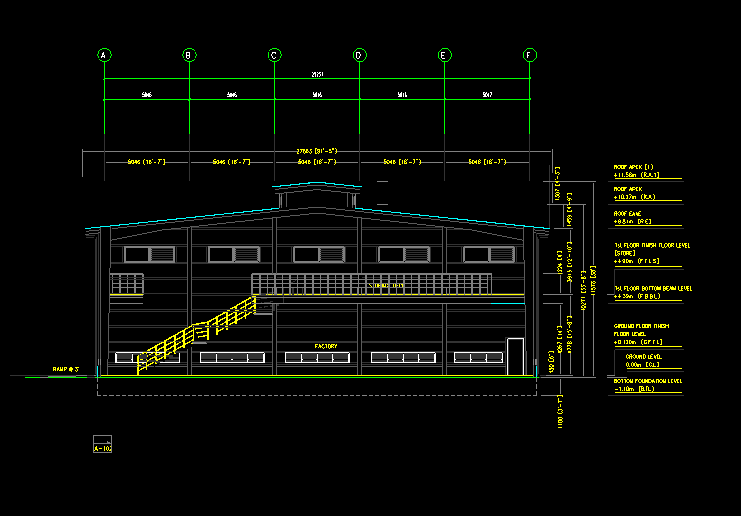

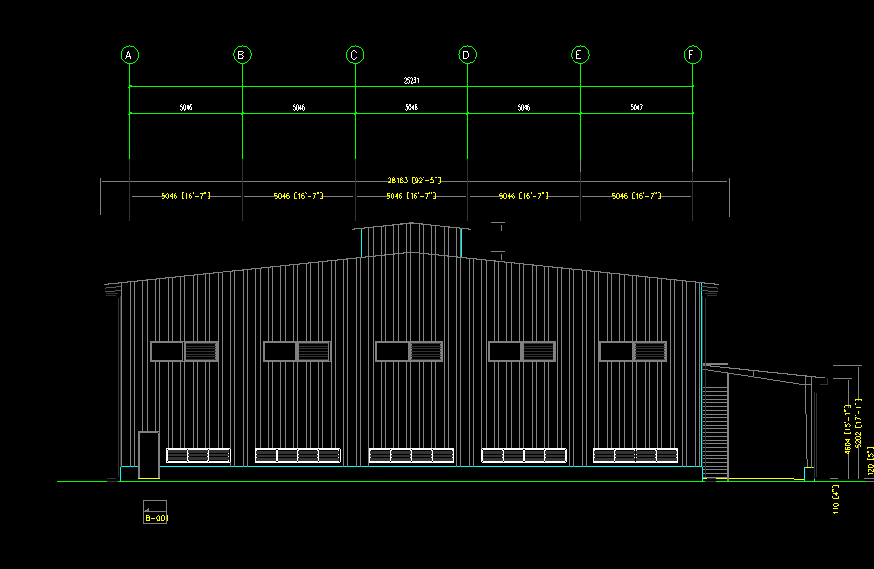

The steel structure workshop layout and elevation are designed as follows:

Ⅱ- Confirmation drawings -Production-QC

Ⅲ Erection

1.5 DEFECT & PROTECTION DURING DELIVERY

During Delivery all delicate workshop materials shall be carefully handled and stored under cover in a manner to prevent deformation and damage to the materials and to prevent rusting and the accumulation of mud, dirt or other foreign matter on the metal work.

For further information feel free to contact us.

E-mail: sales@zyminfra.com

TAG:steel workshop